Radical Solution to the Dusting Concrete Problem: Potassium Silicate and CONCRETE FIX Effect

Solution to the Dusting Concrete Problem: Beton Fix

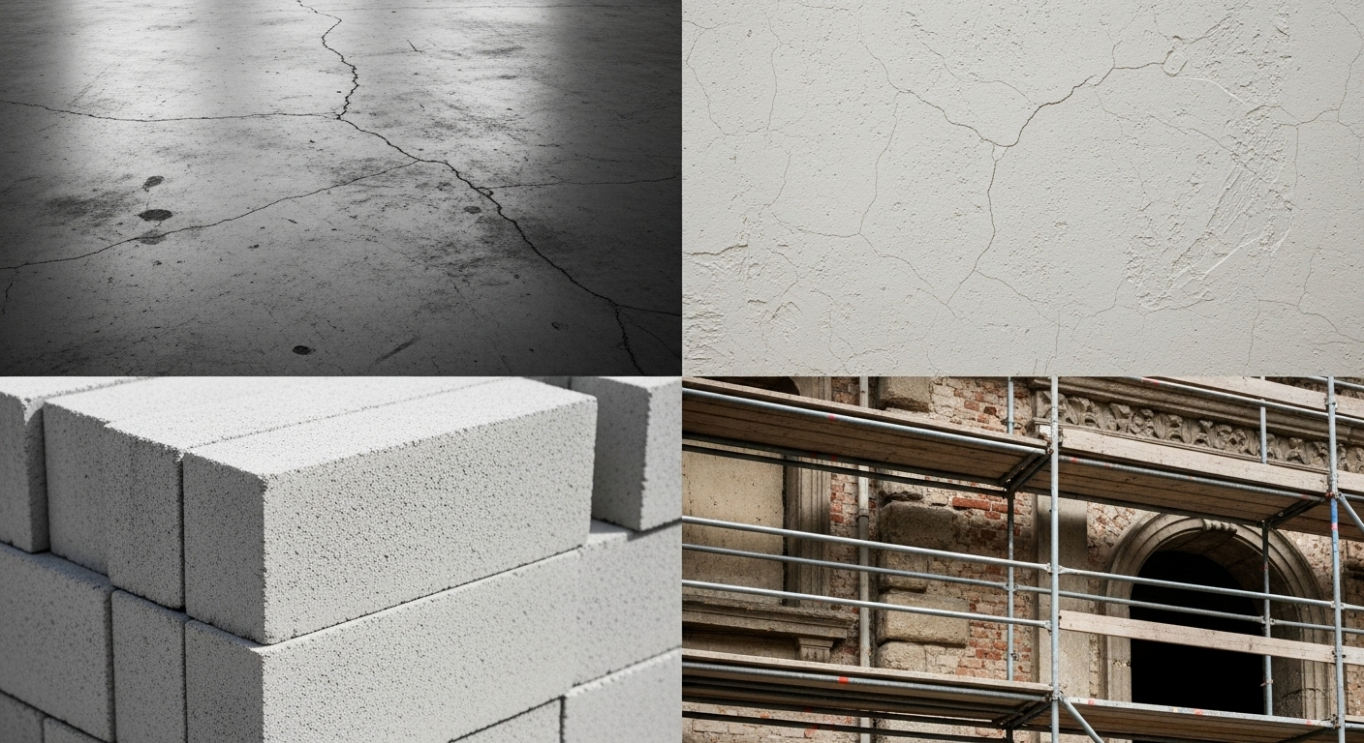

Whether it's concrete floors in industrial facilities, garages, warehouses, or the plaster in historical buildings that have weathered over time, they all share a common problem: dust and abrasion on the surface. This seemingly simple problem is actually a sign of structural weakness and a chronic problem that cannot be resolved with traditional coatings. This is precisely where potassium silicate technology, and the Beton Fix product based on this technology, offer a radical and permanent solution.

Chemical Reaction

Beton Fix is based on pure liquid potassium silicate, a natural inorganic compound, and other organic binders. The secret of this product is not to temporarily coat the surface, but to form a permanent chemical bond with it. This chemical reaction is called "silicification."

When the product is applied to a highly absorbent, dusty concrete or plaster surface, the potassium silicate solution penetrates deep into the pores of the material. There, it chemically reacts with calcium hydroxide, one of the primary components of concrete, to form water-insoluble, extremely hard calcium silicate hydrate (CSH) gels.

An In-Depth Look at the Advantages of Concrete Fix

With its silicification reaction, Beton Fix has a number of unique advantages that distinguish it from its competitors:

Permanent and Non-degradable Bond: The CSH bonds formed become part of the original concrete's structural fabric. This is a "fusion" process, not an adhesion. Therefore, the problems encountered with organic polymer coatings, such as peeling, swelling, or separation over time, are avoided.

Deep Penetration and Overall Strengthening: The process doesn't just occur on the surface. As potassium silicate penetrates deeper, consolidation begins below the surface, uniformly strengthening the material's internal structure. This protection is far more effective than coatings that only provide a thin film of protection.

- Fully Breathable Structure: Beton Fix does not form a film on the surface. It does not block the pores of the applied surface, allowing the concrete to "breathe"—that is, to allow water vapor to pass through. Because moisture inside can escape, the risk of swelling and mold growth beneath the surface is eliminated.

- Inorganic and Environmentally Friendly Formula: Contains almost no organic solvents (VOCs), is non-flammable, and does not emit toxic fumes during application. This is a major advantage for both the user's health and the environment, and can be used safely even in enclosed spaces.

Areas of Use for Beton Fix: Not Limited to Concrete Only

Beton Fix also provides positive results on other highly absorbent mineral surfaces:

- Industrial Concrete Floors

- Lime and Cement Based Interior / Exterior Plasters

- Briquette and Aerated Concrete Walls

- Mineral-Based Surfaces in Historical Building Restorations

Beton Fix is a product that doesn't "cover up" dust problems, but rather "solves them at their root." The chemical silification process provided by potassium silicate makes it a much smarter and more economical option than expensive and laborious surface replacements or repeated temporary coatings.